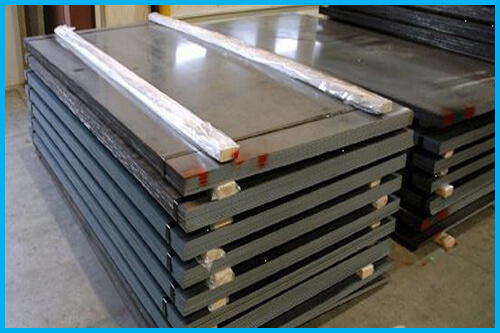

Looking for steel solutions that deliver unmatched durability and long-lasting performance under extreme conditions? Wear plates are designed to withstand abrasion, impact, and high-stress operations, making them the preferred choice for industries like mining, construction, and heavy machinery. Trusted for their toughness and resistance, wear plates provide a cost-effective solution for protecting equipment and reducing maintenance downtime.

Looking for steel solutions that deliver unmatched durability and long-lasting performance under extreme conditions? Wear plates are designed to withstand abrasion, impact, and high-stress operations, making them the preferred choice for industries like mining, construction, and heavy machinery. Trusted for their toughness and resistance, wear plates provide a cost-effective solution for protecting equipment and reducing maintenance downtime.

Why Buyers Prefer Wear Plates

Buyers consistently choose wear plates because they combine strength, abrasion resistance, and adaptability. Their high performance ensures industrial equipment operates efficiently and lasts longer, saving both time and costs.

Key benefits of wear plates include:

-

Superior abrasion resistance for extended service life

-

High impact toughness to withstand heavy-duty operations

-

Cost efficiency through reduced replacement frequency

-

Versatility for applications in mining, construction, and transport

-

Ease of fabrication with excellent welding and machining properties

-

Consistent quality meeting industrial and international standards

By selecting wear plates, businesses reduce operational interruptions and ensure optimal productivity across demanding environments.

Technical Specifications of Wear Plates

Chemical Composition (Typical %)

-

Carbon (C): 0.25–0.50%

-

Manganese (Mn): 0.80–1.50%

-

Chromium (Cr): 0.30–1.50%

-

Nickel (Ni): 0.30–0.70%

-

Molybdenum (Mo): 0.20–0.50%

-

Phosphorus (P): ≤0.025%

-

Sulfur (S): ≤0.020%

This composition ensures a balance between hardness, toughness, and weldability.

Mechanical Properties

-

Hardness: 400–600 BHN (depending on grade)

-

Yield Strength: 500–1000 MPa

-

Tensile Strength: 550–1100 MPa

-

Elongation: 10–20%

-

Impact Toughness: 30–50 J at -20°C

These properties make wear plates ideal for high-abrasion and high-impact applications.

Available Forms

-

Hot-rolled plates

-

Quenched and tempered plates

-

Cut-to-size sheets

-

Pre-fabricated components for industrial machinery

Applications

-

Mining equipment (bucket liners, crushers, chutes)

-

Construction machinery (excavators, loaders, bulldozers)

-

Transport vehicles (dump trucks, hoppers)

-

Heavy-duty industrial equipment requiring abrasion protection

International Standards

Wear plates comply with globally recognized standards, ensuring quality and reliability:

-

UNS: G41000 / G41300

-

ASTM: ASTM A514, ASTM A517

-

ASME: ASME SA-514 / SA-517

-

DIN/EN: EN 10025-6, EN 10250

Adherence to these standards guarantees consistent performance and international acceptance.

Regional Focus

-

India: Mining, construction, and heavy machinery industries

-

Germany: Industrial fabrication and transportation equipment

-

UK: Structural components and wear-resistant machinery

-

UAE: Oil, gas, and construction machinery requiring high durability

Why Buyers Should Partner with Vandan Steel & Engg.co

Sourcing premium wear plates requires a reliable partner. Vandan Steel & Engg.co offers:

-

Mill Test Certificates (MTCs) for complete material traceability

-

Flexible MOQs to accommodate both bulk and smaller orders

-

Efficient logistics for timely domestic and international delivery

-

Technical support for grade selection, welding, and fabrication

-

Consistent high-quality supply to keep your projects on track

With Vandan Steel & Engg.co, buyers receive high-performance wear plates backed by expertise, service, and on-time delivery.

Contact Vandan Steel & Engg.co

Ensure your machinery and structures are protected with the most durable wear plates available. Optimize performance, reduce maintenance costs, and enhance operational efficiency.

Vandan Steel & Engg.co

???? 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004

???? +91-8828813630

✉️ [email protected]

Request your quote today and experience the reliability, durability, and performance of premium wear plates for your industrial projects.